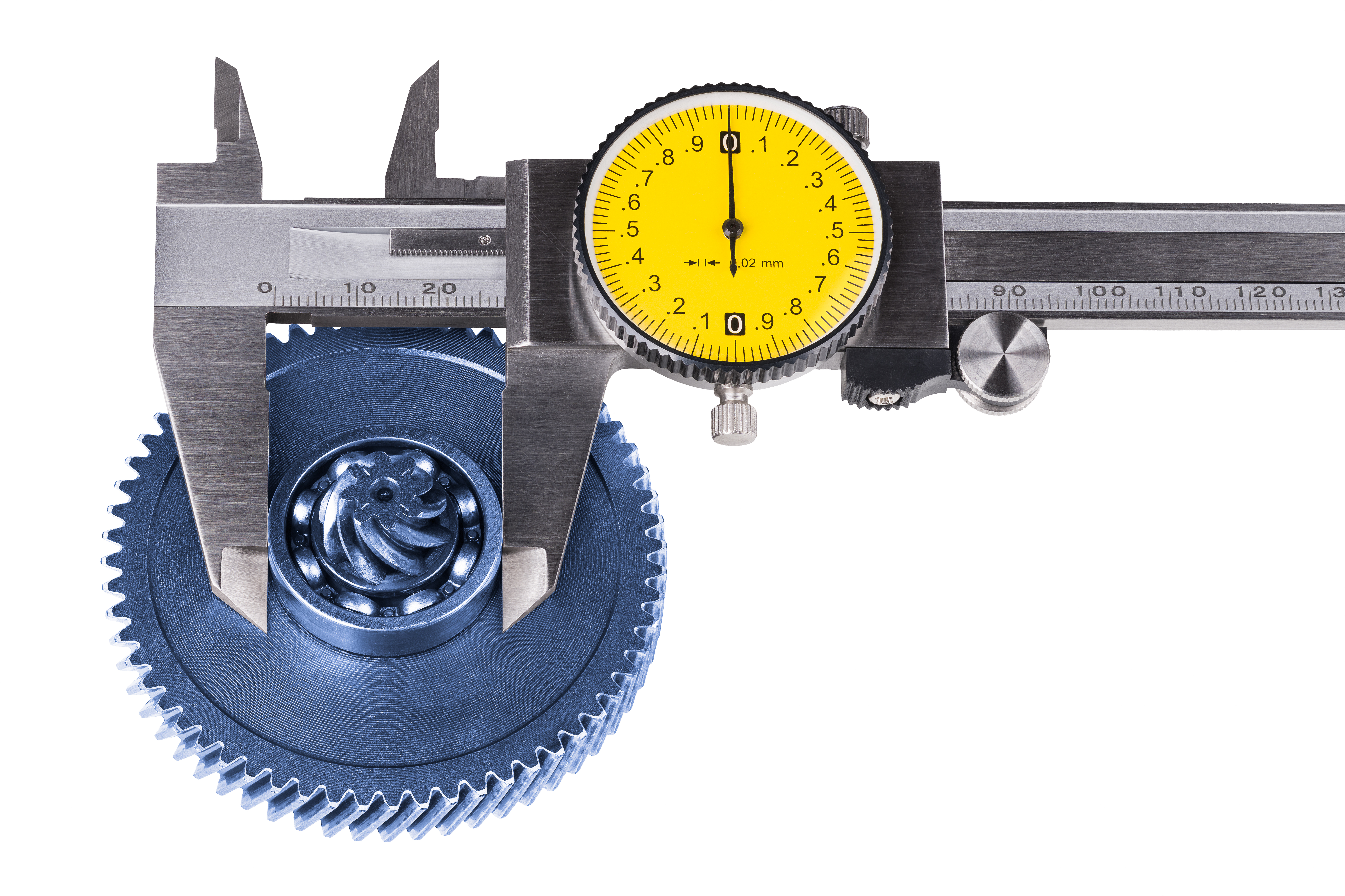

- Measuring Instruments

- Aerospace Tools

-

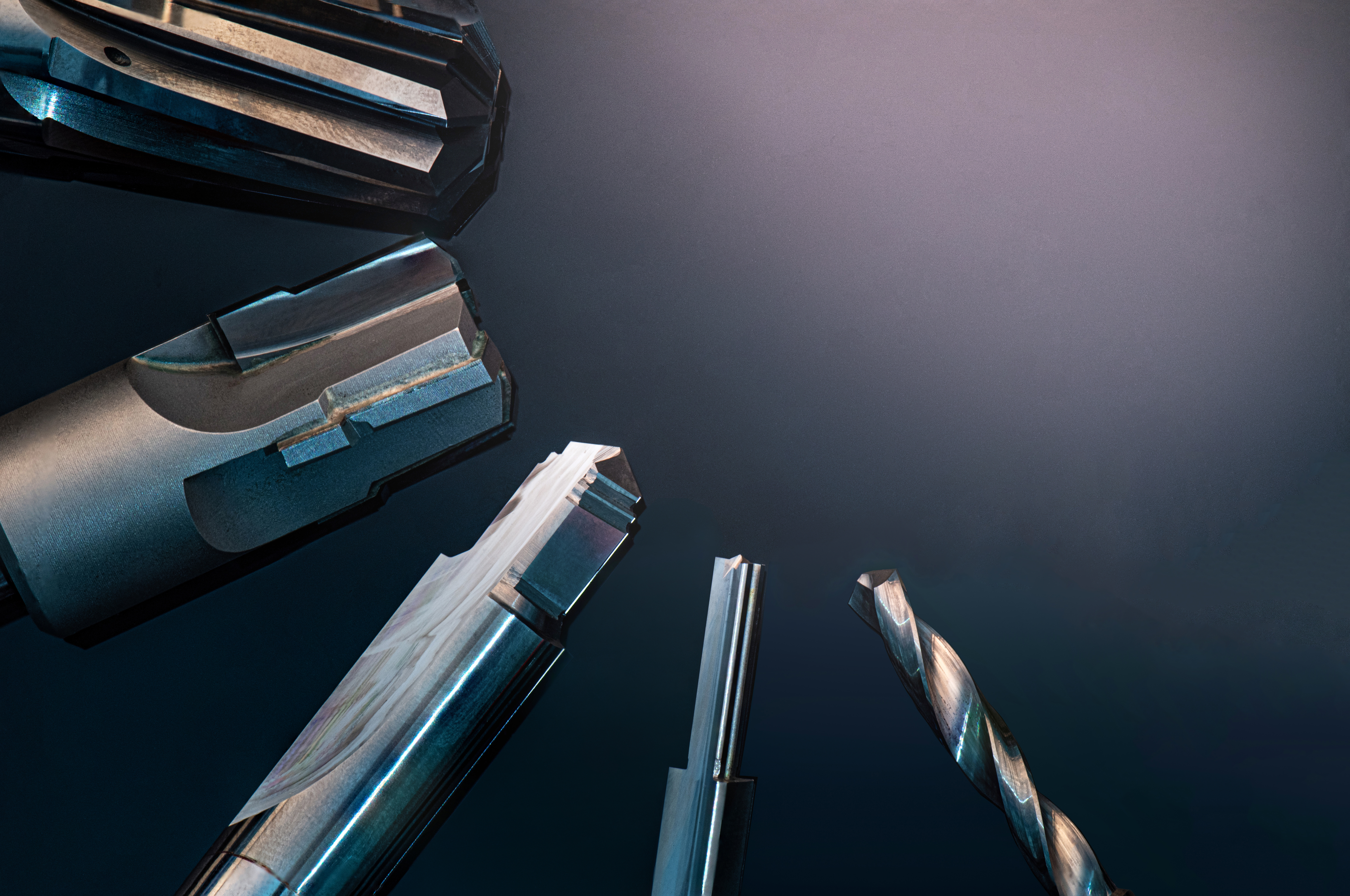

Carbide /Hss Cutting Tools

-

Drills

- Stub Drills

- Jobber Drills

- Ratio Drills (L/D 3)

- Ratio Drills (L/D 5)

- Ratio Drills (L/D 7)

- 3 Flute Drills

- 3 Flute Drills (Through Coolant)

- Step Drills - 2 Flute Twist Drills

- Micro Drills

- Spade Drills

- Deep Hole Drills (L/D 15)

- Centre Drills (Form A)

- Core Drills - Standard Series

- Core Drills - Long Series

-

Endmills

- End Mills 4 Flute

- End Mills 3 Flute

- End Mills 2 Flute

- End Mills 1 Flute

- End Mills -Inches Series

- Vibration Free End Mills

- Power End Mills

- End Mills For Aluminum Machining - Standard Series

- End Mills For Aluminum Machining - Long Series

- End Mills For Aluminum Machining - Extra Long Series

- End Mills For Aluminum Machining - Inches Series

- Slot Mills - Standard Series

- Slot Mills - Long Series

- Slot Mills - Extra Long Series

- Slot Mills - Inches Series

- High Helix End Mills

- Tough Mill

- Roughing End Mills - Standard Series

- Roughing End Mills - Long Series

- Roughing End Mills - Extra Long Series

- Roughing End Mills - Inches Series

-

Ballnose Endmills

- Ball Nose End Mills 2 Flute - Standard Series

- Ball Nose End Mills 2 Flute - Long Series

- Ball Nose End Mills 2 Flute - Extra Long Series

- Ball Nose End Mills 2 Flute - Inches Series

- Ball Nose End Mills 4 Flute - Standard Series

- Ball Nose End Mills 4 Flute - Long Series

- Ball Nose End Mills 4 Flute - Extra Long Series

- Ball Nose End Mills 4 Flute - Inches Series

-

Drills

- Inserts

- Deep Hole Drilling

- Saw Blades

-

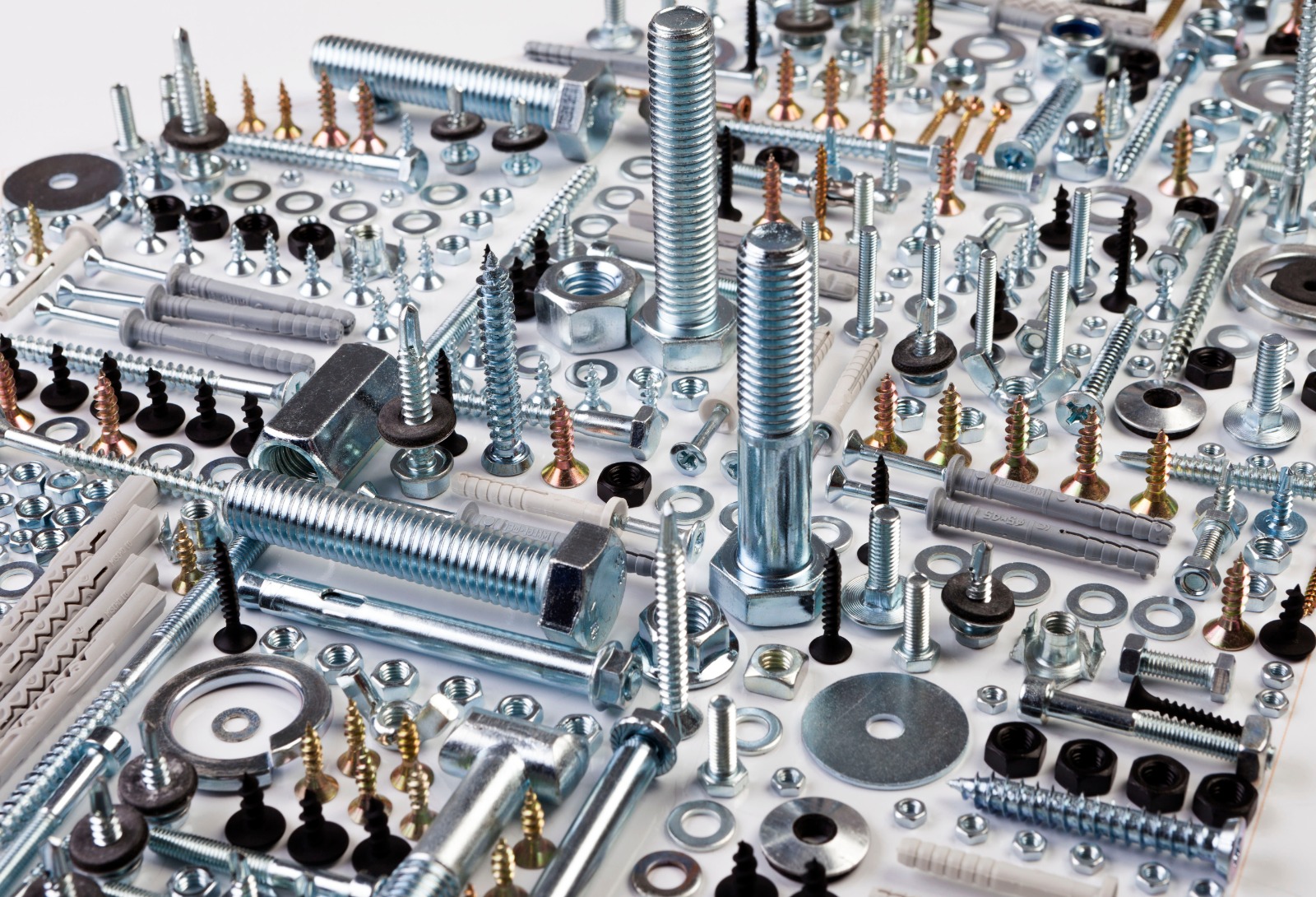

Fasteners

- Whitemetel And Ball Bearings

- Tungsten Carbide

- Square And Round Hss Tool Bits

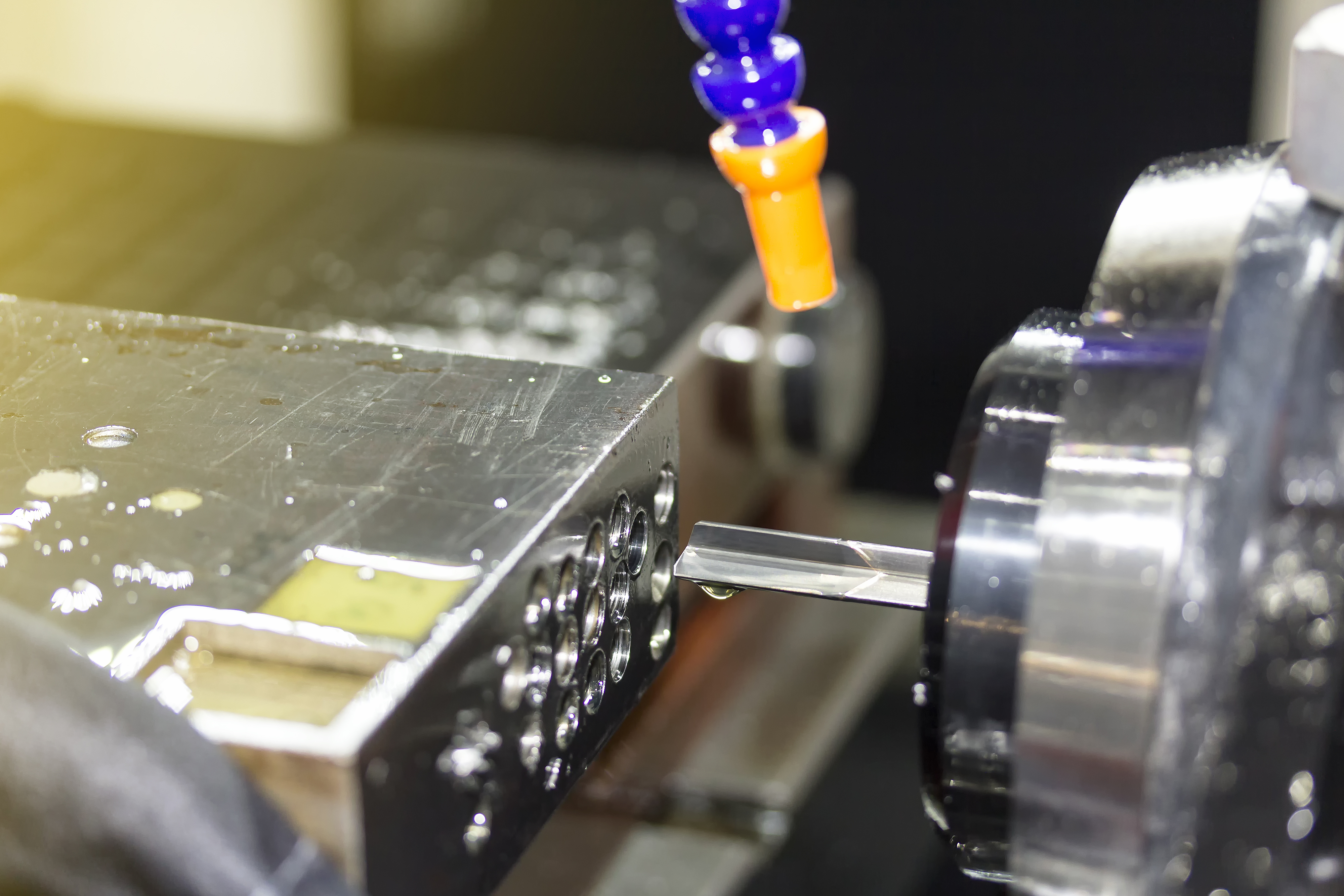

- CNC Machine Tools

-

Abrasives Technologies

-

Flap Wheels On Flange

-

Shaft Mounted Flap Wheel

-

Aluminium Oxide Reinforced Spiral Bands

-

Strip-It Shaft-Mounted Wheels

-

Aluminium Oxide Wheels

-

File Brush

-

Shaft Mounted Circular Wire Brush Crimped And Twisted

-

Cup Wire Brush Twisted

-

Circular Wire Brush Twisted

-

Circular Wire Brush Crimped

-

Tube Cleaning Brush

-

Flap Wheels On Flange

- Diamond /CBN Grinding Wheels

- Brazed Tools

-

Robotic Tools & Equipments

- Safety Equipments & Others

Brazed Tools

Product Full Description

Brazed tools are highly versatile cutting instruments that exhibit exceptional performance in a wide range of machining operations. These tools are created by bonding a layer of hard material, such as carbide or ceramic, to a softer tool body through the brazing process. This fusion generates a robust and reliable connection that enables the tools to withstand elevated cutting forces and temperatures. With their fine micrograin structure, brazed micrograin tools deliver superior hardness and wear resistance.

Brazed pipe tube cutoff tools offer precise and clean cuts for pipes and tubes, while brazed straight turning tools provide high rigidity and stability for heavy cutting loads. Square nose utility tools, when brazed, offer exceptional versatility, and brazed cutoff tools ensure efficient cutting and clean parting-off operations. Brazed threading tools are designed for threading applications, while end cutting offset brazed tools excel in milling and profiling tasks. For enlarging or finishing holes, brazed round shank boring tools provide accuracy and stability. Lastly, special brazed tools cater to unique machining requirements, custom designs, and optimized tooling for specific materials or processes. In essence, brazed tools are renowned for their superior cutting performance, durability, and adaptability across diverse machining operations.